Cross-flow FRP cooling tower HT

Structural features

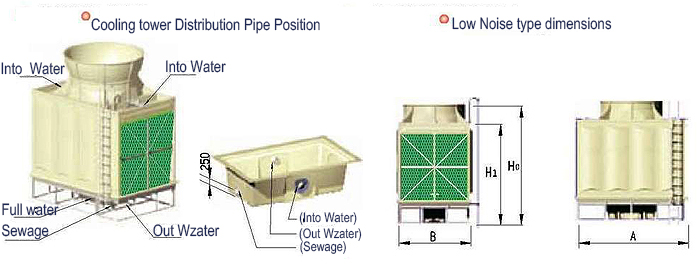

Cross-flow FRP cooling tower using both sides into the wind, by the top of the fan, so that the air through the tower on both sides of the filler, and hot water for gas heat exchange, hot and humid air and then row out of the tower. The filler adopts a point wave sheet with convex points on both sides, which binds the point wave plate to the whole through the mounting head, in order to improve the rigidity, the convex point on both sides can also avoid direct dripping, thus improving the water film formation ability, and the filler tail is provided with water collection measures.

Model specifications

Model code and significance of cross-flow FRP cooling tower: A case study of ht3-450l

HT---Cross-flow FRP cooling tower

3---The parallel composition of three cooling towers

Total---Traffic is 450 cubic meters per hour

L---low noise

Performance & amp; selection

1, design parameters: Standard operating conditions: water inlet temperature T1=37℃, effluent temperature T2=32℃, design wet ball temperature Τ=28℃, that is, water temperature drop t=5℃, high cooling amplitude T2-τ=4℃

2, the selection of information water Q, water inlet temperature T1, effluent temperature T2 and design wet ball temperature tau, and then according to the selection table to investigate the required model.

3, the operating weight according to the tower body water storage half of the depth calculation, if filled with water calculation should be multiplied by 1.5.

4, this series of cooling tower for the coldest monthly average temperature is not less than 10 ℃ of the area, when the temperature is too low to use, should consider the pipeline and sink icing problem, especially in the winter intermittent operation process, the pump directly by the tower in the tank of the circulatory system, but also should be considered to avoid the problem of freezing, if necessary, need to

5, the applicable water temperature does not exceed 65 ℃, such as more than 65 ℃, when ordering should be put forward water temperature requirements, in order to consider when selecting materials, if there is flame retardant or refractory requirements, should be in accordance with the local fire department on the requirements of FRP Oxygen Index production, should be proposed by the user beforehand. It is recommended that the user choose Flame-retardant FRP for the cross-flow tower mounted on the roof. Our company produces flame retardant, refractory FRP material, its oxygen index reached ≥31 or ≥ 35, respectively.

6, circulating water turbidity is not less than 50 ml/l, short-term not more than 100 ml/L, should not contain oil and mechanical impurities, if necessary, to take algae and water quality stabilization measures.

7, with water tank distribution hole according to the nominal flow hole, if the actual flow exceeds the nominal flow of 25%, should be explained at the time of ordering.

8, the water pressure of the inlet pipe is about 2~5 mmhg, design should not be too high pressure, otherwise it will produce floating water phenomenon.

9, motors, fans are supporting the supply. The company needs to send a member on-site installation or technical guidance, plus fees.

Single Cooling tower

| Model | Cooling capacity | Dimensions(mm) | Motor | Running Heavy(kg) | ||||||

Circulating Water quantity(m3/h) | Kcal/h*103 | Long A | Width b | Gao H1 | Gao H0 | Fan diameter(mm) | Power | Rated currentI(A) | ||

| KW | ||||||||||

| HT1-80L | 80 | 400 | 3180 | 1660 | 3325 | 3900 | 1350 | 2.2 | 5 | 1600 |

| HT1-100L | 100 | 500 | 3280 | 1880 | 3325 | 3900 | 1470 | 3 | 5 | 1670 |

| HT1-125L | 125 | 625 | 3280 | 1880 | 3325 | 3900 | 1470 | 3 | 6.8 | 1800 |

| HT1-150L | 150 | 750 | 3670 | 2440 | 3470 | 4120 | 1800 | 4 | 8.8 | 2340 |

| HT1-175L | 175 | 875 | 3970 | 2660 | 3470 | 4120 | 2100 | 5.5 | 11.6 | 2760 |

| HT1-200L | 200 | 1000 | 3970 | 2880 | 3470 | 4120 | 2100 | 5.5 | 11.6 | 3105 |

| HT1-225L | 225 | 1125 | 4290 | 3220 | 3470 | 4120 | 2400 | 5.5 | 11.6 | 3270 |

| HT1-250L | 250 | 1250 | 4665 | 3220 | 3470 | 4120 | 2400 | 5.5 | 11.6 | 4220 |

| HT1-300L | 300 | 1500 | 5260 | 3430 | 3470 | 4120 | 3000 | 7.5 | 15.4 | 5610 |

| HT1-350L | 350 | 1750 | 5260 | 3660 | 3470 | 4120 | 3000 | 7.5 | 15.4 | 6200 |

| HT1-400L | 400 | 2000 | 5950 | 3910 | 3970 | 4670 | 3200 | 11 | 24.6 | 6600 |

| HT1-450L | 450 | 2250 | 5950 | 4110 | 3970 | 4670 | 3200 | 11 | 24.6 | 7300 |

| HT1-500L | 500 | 2500 | 6310 | 4460 | 3970 | 4670 | 3400 | 15 | 31.4 | 7500 |

| HT1-600L | 600 | 3000 | 6850 | 4660 | 4470 | 5180 | 3700 | 18.5 | 37.7 | 8500 |

| HT1-700L | 700 | 3500 | 6850 | 4870 | 4470 | 5180 | 3700 | 22 | 44.7 | 9730 |

| HT1-800L | 800 | 4000 | 7780 | 5260 | 4470 | 5180 | 4200 | 22 | 44.7 | 10910 |

| HT1-1000L | 1000 | 5000 | 9450 | 6460 | 4470 | 5180 | 5000 | 30 | 59.5 | 12500 |

| HT1-1200L | 1200 | 6000 | 10500 | 7160 | 4470 | 5180 | 5000 | 37 | 72 | 14000 |

Two cooling towers in parallel

| Model | Dimensions(mm) | Motor | Running Heavy(kg) | |||||||

| Circulating Water quantity(m3/h) | Cooling capacity Kcal/h*103 | Long A | Width b | Gao H1 | Gao H0 | Fan diameter(mm) | Power | Rated currentI(A) | ||

| KW | ||||||||||

| HT2-200L | 200 | 1000 | 3280 | 3660 | 3325 | 3900 | 1470×2 | 3.0×2 | 5.0×2 | 3540 |

| HT2-250L | 250 | 1250 | 3280 | 3660 | 3325 | 3900 | 1470×2 | 3.0×2 | 6.8×2 | 3800 |

| HT2-300L | 300 | 1500 | 3670 | 4780 | 3470 | 4120 | 1800×2 | 4.0×2 | 8.8×2 | 4880 |

| HT2-350L | 350 | 1750 | 3970 | 5220 | 3470 | 4120 | 2100×2 | 5.5×2 | 11.6×2 | 5720 |

| HT2-400L | 400 | 2000 | 3970 | 5660 | 3470 | 4120 | 2100×2 | 5.5×2 | 11.6×2 | 6410 |

| HT2-450L | 450 | 2250 | 4290 | 6340 | 3470 | 4120 | 2400×2 | 5.5×2 | 11.6×2 | 6740 |

| HT2-500L | 500 | 2500 | 4665 | 6340 | 3470 | 4120 | 2400×2 | 5.5×2 | 11.6×2 | 8640 |

| HT2-600L | 600 | 3000 | 5260 | 6760 | 3470 | 4120 | 3000×2 | 7.5×2 | 15.4×2 | 11420 |

| HT2-700L | 700 | 3500 | 5260 | 7220 | 3470 | 4120 | 3000×2 | 7.5×2 | 15.4×2 | 12600 |

| HT2-800L | 800 | 4000 | 5950 | 7720 | 3970 | 4670 | 3200×2 | 11.0×2 | 24.6×2 | 13400 |

| HT2-900L | 900 | 4500 | 5950 | 8120 | 3970 | 4670 | 3200×2 | 11.0×2 | 24.6×2 | 14800 |

| HT2-1000L | 1000 | 5000 | 6310 | 8820 | 3970 | 4670 | 3400×2 | 15.0×2 | 31.4×2 | 15200 |

| HT2-1200L | 1200 | 6000 | 6850 | 9220 | 4470 | 5180 | 3700×2 | 18.5×2 | 37.7×2 | 17200 |

| HT2-1400L | 1400 | 7000 | 6850 | 9640 | 4470 | 5180 | 3700×2 | 22.0×2 | 44.7×2 | 19660 |

| HT2-1600L | 1600 | 8000 | 7780 | 10420 | 4470 | 5180 | 4200×2 | 22.0×2 | 44.7×2 | 22020 |

| HT2-2000L | 2000 | 10000 | 9450 | 12820 | 4470 | 5180 | 5000×2 | 30.0×2 | 59.5×2 | 25200 |

Three cooling towers in parallel

| Model | Dimensions(mm) | Fan diameter(mm) | Motor | Running Heavy(kg | ||||||

| Circulating Water quantity(m3/h) | Cooling capacity Kcal/h*10 | Long A | Width b | Gao H1 | Gao H0 | Power | Rated currentI(A) | |||

| KW | ||||||||||

| HT3-300L | 300 | 1500 | 3280 | 5440 | 3325 | 3900 | 1470×3 | 3.0×3 | 5.0×3 | 5410 |

| HT3-375L | 375 | 1875 | 3280 | 5440 | 3325 | 3900 | 1470×4 | 3.0×4 | 6.8×3 | 5800 |

| HT3-450L | 450 | 2250 | 3670 | 7120 | 3470 | 4120 | 1800×3 | 4.0×3 | 8.8×3 | 7420 |

| HT3-525L | 525 | 2625 | 3970 | 7780 | 3470 | 4120 | 2100×3 | 5.5×3 | 11.6×3 | 8680 |

| HT3-600L | 600 | 3000 | 3970 | 8440 | 3470 | 4120 | 2100×3 | 5.5×3 | 11.6×3 | 9715 |

| HT3-675L | 675 | 3375 | 4290 | 9460 | 3470 | 4120 | 2100×3 | 5.5×3 | 11.6×3 | 10210 |

| HT3-750L | 750 | 3750 | 4665 | 9460 | 3470 | 4120 | 2400×3 | 5.5×3 | 11.6×3 | 13060 |

| HT3-900L | 900 | 4500 | 5260 | 10090 | 3470 | 4120 | 3000×3 | 7.5×3 | 15.4×3 | 17230 |

| HT3-1050L | 1050 | 5250 | 5260 | 10780 | 3470 | 4120 | 3000×3 | 7.5×3 | 15.4×3 | 19000 |

| HT3-1200L | 1200 | 6000 | 5950 | 11530 | 3970 | 4670 | 3200×3 | 11.0×3 | 24.6×3 | 20200 |

| HT3-1350L | 1350 | 6750 | 5950 | 12130 | 3970 | 4670 | 3200×3 | 11.0×3 | 24.6×3 | 22300 |

| HT3-1500L | 1500 | 7500 | 6310 | 13180 | 3970 | 4670 | 3400×3 | 15.0×3 | 31.4×3 | 22900 |

| HT3-1800L | 1800 | 9000 | 6850 | 13780 | 4470 | 5180 | 3700×3 | 18.5×3 | 37.7×3 | 25900 |

| HT3-2100L | 2100 | 10500 | 6850 | 14410 | 4470 | 5180 | 3700×3 | 22.0×3 | 44.7×3 | 29500 |

| HT3-2400L | 2400 | 12000 | 7780 | 15580 | 4470 | 5180 | 4200×3 | 22.0×3 | 44.7×3 | 33130 |

| HT3-3000L | 3000 | 15000 | 9450 | 19180 | 4470 | 5180 | 5000×3 | 30.0×3 | 59.5×3 | 37900 |

HT cross-flow cooling tower piping size Table

| Tower type | Into Water | Out Water | Full Water | Sewage | Automatic Water Recharge | Manual Water Replenishment | Tower type | Into Water | Out Water | Full Water | Sewage | Automatic Water Recharge | Manual Water Replenishment | |

| HT1-80L | 100×2 | 125 | 80 | 80 | 50 | 50 | HT3-750L | 150×6 | 200×3 | 80×3 | 80×3 | 50×3 | 50×3 | |

| HT1-100L | 100×2 | 125 | 80 | 80 | 50 | 50 | HT3-900L | 150×6 | 200×3 | 100×3 | 80×3 | 50×3 | 50×3 | |

| HT1-125L | 100×2 | 150 | 80 | 80 | 50 | 50 | HT3-1050L | 150×6 | 250×3 | 100×3 | 80×3 | 50×3 | 50×3 | |

| HT1-150L | 125×2 | 150 | 80 | 80 | 50 | 50 | HT3-1200L | 125×12 | 250×3 | 100×3 | 80×3 | 50×3 | 50×3 | |

| HT1-175L | 125×2 | 200 | 80 | 80 | 50 | 50 | HT3-1350L | 125×12 | 250×3 | 100×3 | 80×3 | 50×3 | 50×3 | |

| HT1-200L | 125×2 | 200 | 80 | 80 | 50 | 50 | HT3-1500L | 150×12 | 250×3 | 100×3 | 80×3 | 50×3 | 50×3 | |

| HT1-225L | 125×2 | 200 | 80 | 80 | 50 | 50 | HT3-1800L | 150×12 | 250×3 | 100×3 | 80×3 | 50×6 | 50×6 | |

| HT1-250L | 150×2 | 200 | 80 | 80 | 50 | 50 | HT3-2100L | 150×12 | 300×3 | 100×3 | 80×3 | 50×6 | 50×6 | |

| HT1-300L | 150×2 | 200 | 100 | 80 | 50 | 50 | HT3-2400L | 200×12 | 350×3 | 125×3 | 125×3 | 50×6 | 50×6 | |

| HT1-350L | 150×2 | 250 | 100 | 80 | 50 | 50 | HT3-3000L | 200×18 | 400×3 | 150×3 | 150×3 | 50×6 | 50×6 | |

| HT1-400L | 125×4 | 250 | 100 | 80 | 50 | 50 | HT4-400L | 100×8 | 125×4 | 80×4 | 80×4 | 50×4 | 50×4 | |

| HT1-450L | 125×4 | 250 | 100 | 80 | 50 | 50 | HT4-500L | 100×8 | 150×4 | 80×4 | 80×4 | 50×4 | 50×4 | |

| HT1-500L | 150×4 | 250 | 100 | 80 | 50 | 50 | HT4-600L | 125×8 | 150×4 | 80×4 | 80×4 | 50×4 | 50×4 | |

| HT1-600L | 150×4 | 250 | 100 | 100 | 50×2 | 50×2 | HT4-700L | 125×8 | 200×4 | 80×4 | 80×4 | 50×4 | 50×4 | |

| HT1-700L | 150×4 | 300 | 100 | 100 | 50×2 | 50×2 | HT4-800L | 125×8 | 200×4 | 80×4 | 80×4 | 50×4 | 50×4 | |

| HT1-800L | 200×4 | 350 | 125 | 125 | 50×2 | 50×2 | HT4-900L | 125×8 | 200×4 | 80×4 | 80×4 | 50×4 | 50×4 | |

| HT1-1000L | 200×6 | 400 | 150 | 150 | 50×2 | 50×2 | HT4-1000L | 150×8 | 200×4 | 80×4 | 80×4 | 50×4 | 50×4 | |

| HT1-1200L | 200×6 | 500 | 150 | 150 | 50×2 | 50×2 | HT4-1200L | 150×8 | 200×4 | 100×4 | 80×4 | 50×4 | 50×4 | |

| HT2-200L | 100×4 | 125×2 | 80×2 | 80×2 | 50×2 | 50×2 | HT4-1400L | 150×8 | 250×4 | 100×4 | 80×4 | 50×4 | 50×4 | |

| HT2-250L | 100×4 | 150×2 | 80×2 | 80×2 | 50×2 | 50×2 | HT4-1600L | 125×16 | 250×4 | 100×4 | 80×4 | 50×4 | 50×4 | |

| HT2-300L | 125×4 | 150×2 | 80×2 | 80×2 | 50×2 | 50×2 | HT4-1800L | 125×16 | 250×4 | 100×4 | 80×4 | 50×4 | 50×4 | |

| HT2-350L | 125×4 | 200×2 | 80×2 | 80×2 | 50×2 | 50×2 | HT4-2000L | 150×16 | 250×4 | 100×4 | 80×4 | 50×4 | 50×4 | |

| HT2-400L | 125×4 | 200×2 | 80×2 | 80×2 | 50×2 | 50×2 | HT4-2400L | 150×16 | 250×4 | 100×4 | 100×4 | 50×8 | 50×8 | |

| HT2-450L | 125×4 | 200×2 | 80×2 | 80×2 | 50×2 | 50×2 | HT4-2800L | 150×16 | 300×4 | 100×4 | 100×4 | 50×8 | 50×8 | |

| HT2-500L | 150×4 | 200×2 | 80×2 | 80×2 | 50×2 | 50×2 | HT4-3200L | 200×16 | 350×4 | 125×4 | 125×4 | 50×8 | 50×8 | |

| HT2-600L | 150×4 | 200×2 | 100×2 | 80×2 | 50×2 | 50×2 | HT5-500L | 100×10 | 125×5 | 80×5 | 80×5 | 50×5 | 50×5 | |

| HT2-700L | 150×4 | 250×2 | 100×2 | 80×2 | 50×2 | 50×2 | HT5-625L | 100×10 | 150×5 | 80×5 | 80×5 | 50×5 | 50×5 | |

| HT2-800L | 125×8 | 250×2 | 100×2 | 80×2 | 50×2 | 50×2 | HT5-750L | 125×10 | 150×5 | 80×5 | 80×5 | 50×5 | 50×5 | |

| HT2-900L | 125×8 | 250×2 | 100×2 | 80×2 | 50×2 | 50×2 | HT5-875L | 125×10 | 150×5 | 80×5 | 80×5 | 50×5 | 50×5 | |

| HT2-1000L | 150×8 | 250×2 | 100×2 | 80×2 | 50×2 | 50×2 | HT5-1000L | 125×10 | 200×5 | 80×5 | 80×5 | 50×5 | 50×5 | |

| HT2-1200L | 150×8 | 250×2 | 100×2 | 100×2 | 50×4 | 50×4 | HT5-1125L | 125×10 | 200×5 | 80×5 | 80×5 | 50×5 | 50×5 | |

| HT2-1400L | 150×8 | 300×2 | 100×2 | 100×2 | 50×4 | 50×4 | HT5-1250L | 150×10 | 200×5 | 80×5 | 80×5 | 50×5 | 50×5 | |

| HT2-1600L | 200×8 | 350×2 | 125×2 | 125×2 | 50×4 | 50×4 | HT5-1500L | 150×10 | 200×5 | 100×5 | 80×5 | 50×5 | 50×5 | |

| HT2-2000L | 200×12 | 400×2 | 150×2 | 150×2 | 50×4 | 50×4 | HT5-1750L | 150×10 | 250×5 | 100×5 | 80×5 | 50×5 | 50×5 | |

| HT3-300L | 100×6 | 125×3 | 80×3 | 80×3 | 50×3 | 50×3 | HT5-2000L | 125×20 | 250×5 | 100×5 | 80×5 | 50×5 | 50×5 | |

| HT3-375L | 100×6 | 150×3 | 80×3 | 80×3 | 50×3 | 50×3 | HT5-2250L | 125×20 | 250×5 | 100×5 | 80×5 | 50×5 | 50×5 | |

| HT3-450L | 125×6 | 150×3 | 80×3 | 80×3 | 50×3 | 50×3 | HT5-2500L | 150×20 | 250×5 | 100×5 | 80×5 | 50×5 | 50×5 | |

| HT3-525L | 125×6 | 200×3 | 80×3 | 80×3 | 50×3 | 50×3 | HT5-3000L | 150×20 | 250×5 | 100×5 | 100×5 | 50×10 | 50×10 | |

| HT3-600L | 125×6 | 200×3 | 80×3 | 80×3 | 50×3 | 50×3 | HT5-3500L | 150×20 | 300×5 | 100×5 | 100×5 | 50×10 | 50×10 | |

| HT3-675L | 125×6 | 200×3 | 80×3 | 80×3 | 50×3 | 50×3 | HT5-4000L | 200×20 | 350×5 | 125×5 | 125×5 | 50×10 | 50×10 |