Mixed-flow closed cooling tower

Zxz-x mixed-flow closed cooling tower scope of application

closed cooling tower is characterized by a large temperature difference in cooling water import and export and low noise, making it ideal for industrial environments with high noise requirements. such as electronics factories, medical device factories, or factories from residential areas, hospitals, schools and other places very close to the place.

Operating principle of zxz-x mixed-flow closed cooling tower

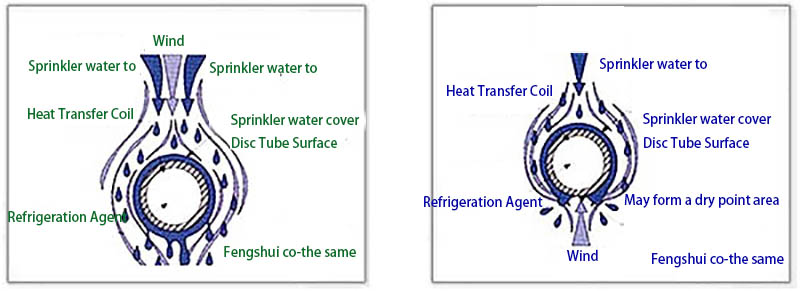

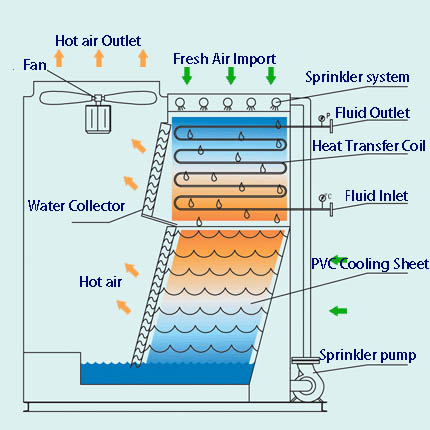

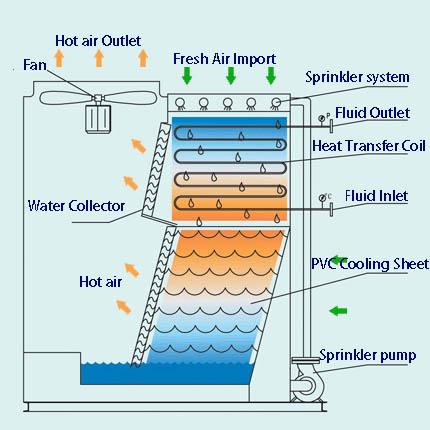

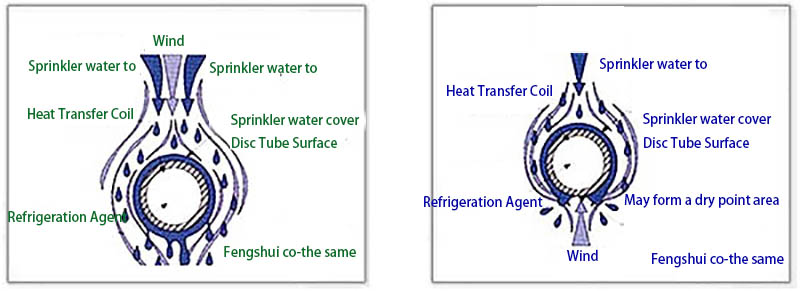

working fluid (water, oil or other liquid) flows in the heat transfer coil, the outer wall of the coil is wrapped in spray water, the heat of the fluid is transmitted through the pipe wall, and the water and air are lined with saturated hot and humid vapour, and the heat is discharged into the atmosphere by the fan. Spraying water reduces temperature through PVC fillers during circulation. From the upper to lower, in the coil area, spray water and the new air into the tower to form a feng shui flow in the same direction, while in the filler section, spray water and the new air of the tower transverse flow. Therefore, the name of the mixed-flow closed cooling tower.

Excellent heat exchange performance: High efficiency heat transfer is realized by using the technology of combination of coil and PVC filler with two heat exchange of feng shui and mixed flow type. As the air and sprinkler water flow through the coil, the sprinkler energy is maximized to cover the surface of the closed cooling tower coil to ensure that the surface of the coil is completely moist. Compared with the structure of the reverse flow of feng shui, the same flow of feng Shui has two advantages: first, to reduce the dry point of the outer wall of the coil and the formation of scale, the second is to speed up the spray water on the coil shedding, so that the sprinkler energy to form a thinner water film, conducive to cooling.

Composition of zxz-x mixed-flow closed cooling tower

Catchment Tray: The structure design of the bottom of the catchment plate tilted to the end of the sewage outlet, which can easily remove the sewage from the catchment tray and precipitate impurities. (See figure below)

Sprinkler pump: Spray pump using non-steering restrictions of high-quality mechanical seals, no leakage, long life. Huizhou Snowman Cooling Equipment Co., Ltd. production of mixed-flow closed cooling tower motor all using 380v,ip55/f grade well-known brands. Special configuration of imported bearings to ensure the long-term reliable operation of the machine pump, with small power, large flow, low noise, excellent performance and so on.

Shell: Huizhou Snowman product shell using imported aluminum-plated zinc plate, it is one of the most corrosion-resistant plate on the market, the service life is 3~6 times the ordinary galvanized plate. and has the advantages of strong heat resistance, high heat resistance, beautiful appearance and so on. Stainless steel plates or other corrosion-resistant materials can be used for high corrosive applications.

Electronic Water descaling instrument: The configuration of advanced electronic water descaling instrument, its use of electronic pulse technology for circulating water anti-scaling, sterilization and algae treatment. All you need to do is turn on the 220V power supply to deal with the water quality of circulating water, effectively avoiding the formation of dirt on the wall and filler of the coil.

Fan: Snowman zxz-x mixed-flow closed cooling tower fan system adopts cooling tower special aluminum alloy axial fan, front tilt type wind vane structure design, streamlined inlet air cylinder, small wind resistance, large air volume, low noise, good performance and high efficiency. The structure without belt rotation reduces the rotating parts, and adopts the fully enclosed self-cooling low noise cooling tower special motor, which has the advantages of small volume, light weight, good starting performance, reliable operation and durability.

![]()

Fasteners: The box of zxz-x mixed-flow closed cooling tower is linked by Stainless steel (304) bolts, and its corrosion resistance is unmatched by ordinary steel bolts, which also brings effective guarantee to the long-term stability of the mixed-flow closed cooling tower.

Closed Cooling tower Coil: If carbon steel pipe is used to make coil, the coil is controlled by high quality seamless fluid, the design pressure is 1.97MPa. Coil welding, assembly and overall hot dip zinc are tested in water by 2.5MPa air tightness (3 times) to ensure no leakage. The overall hot-dip zinc treatment of the condensing coil group enhances the anti-corrosion ability of the coil and extends the service life. If the copper pipe is used to make the coil, the T2 deoxygenation copper tube is used as the heat transfer tube. Design air pressure 1.6MPa. The support plate adopts elastic engineering plastics, and the heat transfer effect is better. Distribution system: Cooling water sprinkler system using large flow anti-clogging flower blue nozzle, to ensure the continuous uniformity of cloth water, spraying on the surface of the coil water, in the action of the wind to allow water to maximize the cover of the surface of the coil, so that water, air and refrigerant full heat exchange, thus improving the heat transfer effect. The nozzle is buttoned on the sprinkler branch pipe and can be easily disassembled when cleaning the nozzle and sprinkler branch.

Water remover: Huizhou snowman zxz-x Mixed-flow closed cooling tower The original detachable water remover adopts corrosion-resistant PVC material, and its structure can effectively remove the wet air moisture from the coil by changing the flow direction of the airflow. Filler heat exchange layer: Specially designed PVC honeycomb cross-flow filler, shortcut transverse wind structure, so that air can quickly take away the heat in the water, unique filler runner, so that the water flow on the filler surface can form a large area of the flow of water film, prolong the cooling time of water in the filler, improve the water cooling effect. It has the advantages of small wind resistance coefficient, anti-aging, not easy deformation and so on.

Characteristics of zxz-x mixed-flow closed cooling tower

Convenient transportation and installation: the use of the upper and lower box standard components transport, on-site installation of the way, greatly facilitate the transport and installation of products.

Low failure rate: Both fans and pumps are made of SKF premium bearings, and there are no other running wear parts. The fan adopts the direct-linked structure, the transmission loss caused by the no belt wheel structure, the noise is small, the failure rate is low.

Easy maintenance: The use of humanized structure design, oversized access door, spacious interior space, maintenance personnel in the product can easily carry out a variety of maintenance work.

Low operating costs, energy saving and environmental protection: due to the unique structural form of this product, as well as its unique high thermal performance, so the cooling effect is good, running power saving, water saving, low noise does not pollute the environment, is a real energy-saving and environmental protection products.

To achieve non-stop maintenance: This product can be in the case of non-stop machine parts of the equipment for maintenance.

Product structure of mixed-flow closed cooling tower

Heater

In the cold area of winter use of cooling tower occasions, circulating water, scattered water easy to freeze, resulting in piping, tower parts of the rupture. In order to prevent the occurrence of this type of accident, we recommend the use of antifreeze components, such as electric heaters, if you need other antifreeze methods can contact the company.

Forward closed windshield Shield

When the protection of heat loss is required, a coil air inlet shield with a forward closed wind door and a windshield driver can be used.

Electronic Water Level Control kit

It can be used as an alternative to the filling valve when more precise or durable water level control is required. Includes an inductive water level control device mounted in a water tray and a slow-closed solenoid valve on a cooling tower recharge connection pipe.

Sink Cleaning Piping

Used to remove debris that may be deposited in the cold water tray of the cooling tower, which is installed in a cold water plate and can be connected to a sand filter device by bypass.

Bacteria, mucus and algae control devices

Bacteria, mucus and algae growth are controlled by automatic spraying of accurate doses and extremely low concentrations of natural iodine into circulating water.

High temperature resistant heat dissipation sheet

When entering the cooling tower fluid temperature is high, you can consider the selection, specific requirements can contact with my company.

Stand-in fan system

For multi-fan model cooling tower to provide a dedicated motor and drive device, can achieve the operation of each typhoon machine alone.

Vibration jump-off switch

Can be equipped with mechanical or electronic vibration jump switch, in order to effectively prevent the equipment due to the drive system vibration is too large and malfunction.

External overhaul facilities

From the bottom of the equipment to the fan mounting layer equipped with aluminum climbing ladder, can also be equipped with climbing ladder fan installation extension platform, access door platform and external motor platform, in order to enter the equipment for inspection.

Technical parameter table of mixed-flow closed cooling tower:

| Model | Refrigeration capacity×103 Kcal/h | Fan | Sprinkler pump | Import & amp; Export Trail | Dimensions | Weight Kg | ||||

| Airm3/h | PowerKW | A | Flow m3/h | PowerKW | DN | L×W×H | Net | Running Heavy | ||

| ZXZ-X60G | 430 | 60000 | 4 | 1 | 45 | 1.5 | 100 | 2110×2410×4225 | 3370 | 4300 |

| ZXZ-X65G | 475 | 60000 | 4 | 1 | 45 | 1.5 | 100 | 2110×2410×4225 | 3580 | 4500 |

| ZXZ-X70G | 495 | 65000 | 5.5 | 1 | 45 | 1.5 | 100 | 2110×2410×4225 | 3650 | 4600 |

| ZXZ-X80G | 550 | 62000 | 4 | 1 | 65 | 2.2 | 100 | 2210×3030×4265 | 4060 | 5100 |

| ZXZ-X85G | 595 | 75000 | 5.5 | 1 | 65 | 2.2 | 100 | 2210×3030×4265 | 4150 | 5200 |

| ZXZ-X95G | 670 | 75000 | 5.5 | 1 | 65 | 2.2 | 125 | 2210×3030×4265 | 4430 | 5500 |

| ZXZ-X100G | 700 | 75000 | 5.5 | 1 | 65 | 2.2 | 125 | 2210×3030×4965 | 4880 | 6200 |

| ZXZ-X105G | 735 | 87000 | 7.5 | 1 | 65 | 2.2 | 125 | 2210×3030×4965 | 4950 | 6300 |

| ZXZ-X130G | 900 | 2×65000 | 2×5.5 | 2 | 100 | 3 | 150 | 3860×2410×4225 | 5780 | 7200 |

| ZXZ-X135G | 960 | 2×60000 | 2×4 | 2 | 100 | 3 | 150 | 3860×2410×4225 | 6020 | 7800 |

| ZXZ-X150G | 1050 | 2×72000 | 2×7.5 | 2 | 100 | 3 | 150 | 3860×2410×4225 | 6260 | 8100 |

| ZXZ-X165G | 1165 | 2×62000 | 2×4 | 2 | 130 | 4 | 150 | 4070×2610×4965 | 6830 | 9500 |

| ZXZ-X185G | 1285 | 2×75000 | 2×5.5 | 2 | 130 | 4 | 200 | 4070×2610×4965 | 6970 | 9700 |

| ZXZ-X190G | 1335 | 2×87000 | 2×7.5 | 2 | 130 | 4 | 200 | 4070×2610×4965 | 7100 | 9800 |

| ZXZ-X205G | 1420 | 2×75000 | 2×5.5 | 2 | 130 | 4 | 200 | 4070×3030×4965 | 7520 | 10200 |

| ZXZ-X215G | 1490 | 2×87000 | 2×7.5 | 2 | 130 | 4 | 200 | 4070×3030×4965 | 7680 | 10300 |

| ZXZ-X225G | 1575 | 3×60000 | 3×4 | 3 | 130 | 4 | 200 | 5610×2410×4825 | 7920 | 10500 |

| ZXZ-X235G | 1620 | 3×65000 | 3×5.5 | 3 | 130 | 4 | 200 | 5610×2410×4825 | 8150 | 10600 |

| ZXZ-X245G | 1690 | 3×72000 | 3×7.5 | 3 | 130 | 4 | 200 | 5610×2410×4825 | 8280 | 10700 |

| ZXZ-X255G | 1765 | 3×87000 | 3×7.5 | 3 | 170 | 5.5 | 200 | 5910×2610×4965 | 9020 | 12600 |

| ZXZ-X275G | 1935 | 3×85000 | 3×5.5 | 3 | 170 | 5.5 | 250 | 5910×2610×4965 | 9850 | 12900 |

| ZXZ-X285G | 2010 | 3×87000 | 3×7.5 | 3 | 170 | 5.5 | 250 | 5910×2610×4965 | 10100 | 13100 |

| ZXZ-X310G | 2140 | 3×75000 | 3×5.5 | 3 | 170 | 5.5 | 250 | 5910×3030×4965 | 10600 | 13500 |

| ZXZ-X325G | 2245 | 3×70000 | 3×7.5 | 3 | 170 | 5.5 | 250 | 5910×3030×4965 | 10800 | 13900 |

| ZXZ-X375G | 2600 | 3×110000 | 3×7.5 | 3 | 170 | 5.5 | 250 | 5910×3030×4965 | 12200 | 15500 |